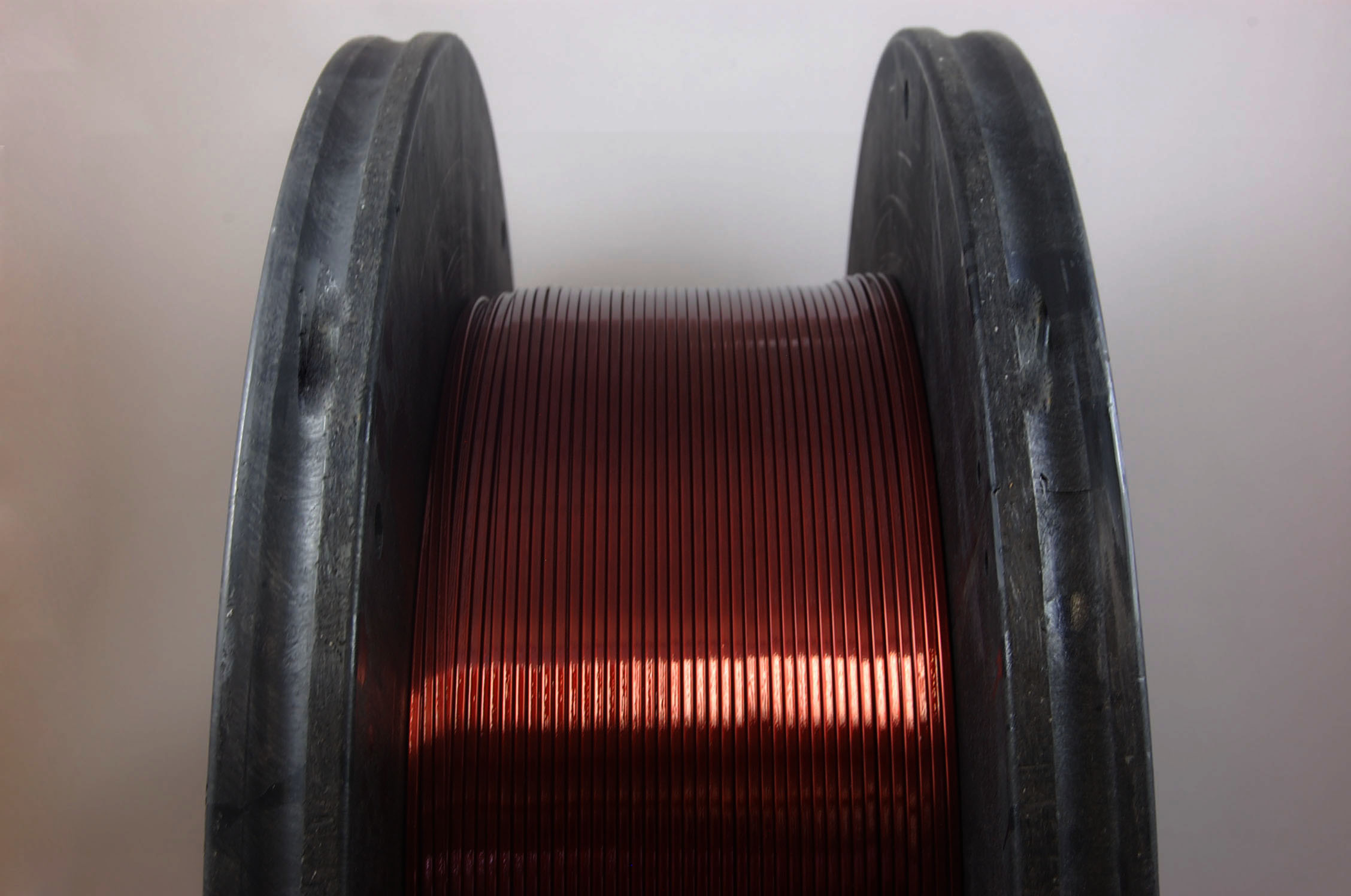

Magnet/Winding Wire

GP/MR-EXTRA

Roll over image to zoom in

Images are representative of product listed and may not be actual product.

#7 Heavy GP/MR-EXTRA Round MW 37 Copper Magnet Wire 220°C, copper, 250 LB 24" reel (average wght.)

Part: W7.0HGPMREX24

Manufacturer: Essex Solutions

Manufacturer #: C250XX00070024A

GP/MR-EXTRA® has an improved insulation system that has been engineered to enhance adhesion, scrape abrasion, and chemical resistance with improved thermal properties. GP/MR-EXTRA® is manufactured utilizing Tris (2-hydroxyethyl) isocyanurate (THEIC) modified polyester basecoat in conjunction with a tough, thermally stable polyamideimide topcoat polymer. Changes to the THEIC polyester basecoat and to the polyamideimide topcoat provide a product with improved abrasion resistance and thermal capability.

GP/MR-EXTRA® magnet wire is recommended but not limited to the following applications:

-form wound coils

-fractional and integral HP motors

-DC motors

-hermetic motors

-power tools

-automotive alternators and generators

-all dry-type transformers, Class 105 through 220

-electronics, all types of coils, Class 105 through 220

- NEMA MW 37

- excellent unilateral scrape abrasion resistance

- very good repeated scrape abrasion resistance

- high moisture and chemical resistance

- excellent heat shock resistance

- excellent adhesion and flexibility

- high thermal endurance and thermoplastic flow

- high burnout-AC overload resistance

- low coefficient of friction

- excellent resistance to refrigerants and replacement refrigerants (for CFC's and HCFC's)

- preferable stripping method is mechanical

| AWG Size | 7.00 |

|---|---|

| Product Type | GP/MR-EXTRA |

| Colour | Copper |

| Temperature Class | Class R-220°C |

| Insulation | Polyester/Polyamideimide |

| Conductor | Copper |

| Shape | Round |

| Standard Type | Heavy Build |

| NEMA Spec | MW 37 |

| Windability | Excellent |

| Chemical Resistance | Excellent |

- form wound coils

- fractional and integral horsepower motors

- hermetic motors

- DC motors

- power tools

- automotive alternators and generators

- all dry-type transformers from Class 105-220

- electronics, all types of coils from Class 105-220

Electrowind is a proud supplier of a broad range of magnet wire and cable products from Essex Furukawa.

Essex Furukawa is the global Leader in Magnet Wire/Winding Wire Manufacturing for Electric Vehicles, Automotive, & Industrial Applications, for major OEM & Tier 1 suppliers. If you don't see the specific Essex Furukawa product you are looking for on our website, we will find it for you. Reach out to Electrowind as your preferred supplier for Essex Furukawa magnet wire, winding wire and cable.

- Packaging Description: 24" Reel (250 LB average weight)

- Product Weight: 265.00 EA

- Product Size: 24.00 x 9.00 x 24.00

$2474.37/EA USD

Availability: 1

Order Minimum Qty: 1

Lead time when 0 in stock: 14 days

Shipping Details

This item is oversized. Oversized items are not eligible for free shipping.

This product is oversized and/or not available for shipping via courier. Please contact Electrowind for shipping rates or we will contact you if shipping rates aren’t available for this product and you place an order for this product on our website.

Purchase Terms & Return Policy

Alternate Products

You might also be interested in

Disclaimer: Electrowind exercises care in producing, composing, editing and distributing the data on this website. Electrowind is not liable for damages resulting from use of any apparent misstatements and/or errors in the data presented on this website. To ensure compatibility with your application, always consult the datasheet before purchasing or using any product in your application.

Skip to main content

Skip to main content